Dr. Clara Lauscher,

Contact

Address

Department of Biochemical and Chemical Engineering

Laboratory of Solids Process Engineering

Emil-Figge-Str. 68

44227 Dortmund

Contents

Abstract

Small particles in the sub micrometer range are used in different application fields such as the pharmaceutical, chemical or food industry. A conventional technique to produce small particles is spray drying. Unfortunately, the spraying process is limited regarding small droplet sizes, so that the development of a new process would be beneficial. The new approach to overcome this limitation is to aerosolize an emulsion instead of the conventional single-phase solution. Since the droplet size also depends on the continuous phase, using emulsification could be beneficial for achieving the desired size reduction.

Description

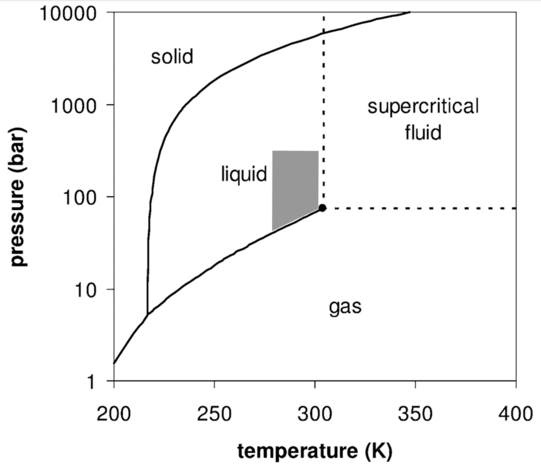

The aim of this study is to investigate the potential to produce an aerosol with droplets in the small micrometer range using emulsification. Therefore, an emulsion of liquid carbon dioxide and a non-miscible liquid (e.g. demineralized water or ethylene glycol) is generated using different emulsification processes. As can be seen in figure 1 the desired working area of the liquid carbon dioxide is at a pressure of about 100 bar and a temperature of 20 °C. After the emulsification process, the high-pressure emulsion is expanded through a nozzle with a short length to diameter ratio, resulting in the spontaneous evaporation of the liquid carbon dioxide. Thus, an aerosol of the droplets previously contained in the emulsion is prepared (see figure 2). For process understanding the droplet formation during the emulsification as well as the droplet breakup during the nebulization will be investigated.

References

- 2005, "Supercritical Carbon Dioxide for Sustainable Polymer Processes," Supercritical Carbon Dioxide, pp. 1-14.

Curriculum Vitae

| Since 2018 | PhD at the Laboratory of Solids Process Engineering, TU Dortmund |

| 2016 - 2017 | M.Sc. Business Administration and Engineering: Mechanical Engineering, RWTH Aachen Master thesis: Experimental analysis of Layer-by-Layer coated ceramic membranes for use in organic solvent nanofiltration (OSN) and in solvent tolerant nanofiltration (STNF) |

| 2012 - 2016 | B.Sc. Business Administration and Engineering: Mechanical Engineering, RWTH Aachen Bachelor thesis: Ecological aspects in material flow cost accounting using the example of manufacturing profiles for modern building |

| 2004 - 2012 | Schloß-Gymnasium Benrath, Düsseldorf |

| Born | March 27th, Weinheim |