Dr. Kevin Hoppe,

Contact

Address

Department of Biochemical and Chemical Engineering

Laboratory of Solids Process Engineering

Room G3-4.24

Emil-Figge-Str. 68

44227 Dortmund

Contents

Abstract

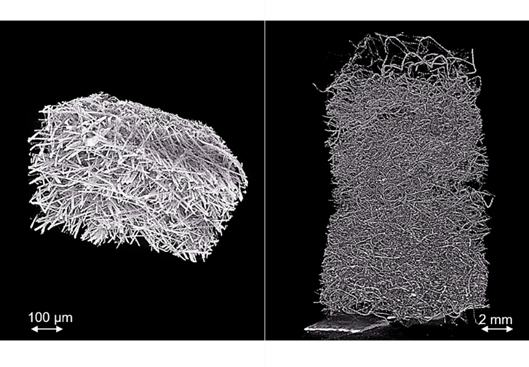

In terms of cleaning gas streams from small up to medium volume flows fibrous filters are one of the most common technologies for separating particles or droplets. Fibrous filters offer several advantageous such as low investment and operating costs. For that reason these filters find applications in a broad field (power plants, spray drying, HEPA-filter for clean rooms, air cabin filters for cars…).

Description

Challenges and limitations of using fibrous filters is their limited separation efficiency for particles in the submicron range (<1µm) and limited life cycles of filter systems as consequence of caking and increase of pressure drop during loading the material with particles [1]. Because of the health hazard of particulate matter [2] there are strict environmental specifications for emitting these particles. For that reason it is desirable to develop fibrous filter systems which are able to deal with this challenges (High separation efficiency, low pressure drop and long life time cycles) under varying operating conditions.

Based on simulations for prediction the performance of fibrous filters novel fibrous filter systems should be developed having improved separation efficiencies.

The aim of this project includes the development of simulations for prediction the performance of fibrous filters under consideration of the filter media structure as well as their experimental validation on microscopic and macroscopic level. Using these tools, the relationship between the different separation mechanism and the filter media structure will be investigated.

References

- Azimian et al. Chemical Engineering and Technology, 41 (5), 928-935, 2018

- Burns et al., Cochrane Database of Systematic Reviews

- Pieloth et al. Environmental Progress and Green Energy, e13423, 1-11, 2020

Curriculum Vitae

| Since 2017 | PhD at Anhalt University of Applied Science (Köthen) in cooperation with the Laboratory of Solids Process Engineering (TU Dortmund) |

| 2015 - 2017 | M.Sc. Biochemical Engineering, TU Dortmund Master thesis: Investigation of scale-up concepts for hot-melt extrusion |

| 2010 - 2015 | B.Sc. Biochemical Engineering, TU Dortmund Bachelor thesis: Hydrodynamics, mass transfer and reactive precipitation at levitated bubbles |

| 2007 - 2010 | Pestalozzi Gymnasium (Unna) |

| 2001 - 2007 | Fridtjof Nansen Realschule (Kamen) |

| Born | 26th June 1991 (Kamen) |