Dr. Maren Zimmermann,

Contact

Address

Department of Biochemical and Chemical Engineering

Laboratory of Solids Process Engineering

Emil-Figge-Str. 68

44227 Dortmund

Contents

Abstract

Recently, pharmaceutical production has been focusing largely on continuous manufacturing due to advantages relating to process efficiency and cost-effectiveness [1]. In this context, the compression of powder on rotary tablet presses is one essential technology.

Description

Tablets are solid single unit dosage forms made from dry powder blends or granules using high compression forces [2]. They are the most common drug delivery system due to numerous advantages including an excellent dosing accuracy, a high patient compliance and an ease of handling. Additionally, high production rates are realized on rotary tablet presses [3].

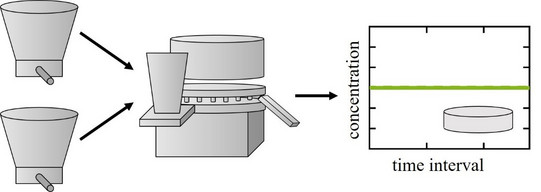

For this unit operation the residence time distribution (RTD) is an important parameter, which is defined as the probability function of the time a particle remains in a unit operation [4]. This is related to the mixing capacity of a system as well as the impact of shear forces applied to particles.

In the context of this work, an in-line method to determine the powder RTD in a rotary tablet press should be implemented. Thereby process knowledge should be gained and the blending characteristic should be analyzed, which shall lead to a process intensification. In this context, the impact of the lubrication method should be investigated additionally.

References

- Buchholz, S., Future manufacturing approaches in the chemical and pharmaceutical industry, Chem Eng Process, 49, 993-995 (2010).

- Fahr, A., Voigt, R., Pharmazeutische Technologie: Für Studium und Beruf, Deutscher Apotheker Verlag, Stuttgart (2015).

- Bauer-Brandl, A., Die Tablette: Handbuch der Entwicklung, Herstellung und Qualitätssicherung, EVC Editio Cantor, Aulendorf (2011).

- Levenspiel, O., Chemical reaction engineering, Wiley, Hoboken (1999).

Curriculum Vitae

| Since 2017 | PhD at the Laboratory of Solids Process Engineering, TU Dortmund |

| 2014 - 2016 | M.Sc. Biochemical Engineering, TU Dortmund |

| 2010 - 2014 | B.Sc. Biochemical Engineering, TU Dortmund |

| 2001 - 2010 | Walburgisgymnasium (Menden) |

| Born | November 13th, Wickede (Germany) |