Vincent Kimmel, M.Sc.

Contact

Telephone

(+49)231 755-6091

Address

Department of Biochemical and Chemical Engineering

Laboratory of Solids Process Engineering

Room G3-4.18

Emil-Figge-Str. 68

44227 Dortmund

Contents

Abstract

Hot melt extrusion (HME) processes are increasingly applied in pharmaceutical research [1]. Therefore, the prediction of optimum process conditions inside the extruder is of particular interest in the development of new material formulations. Within this study, a modeling approach for pharmaceutical HME processes is developed.

Description

The poor solubility of new developed active pharmaceutical ingredients (APIs) is a major challenge in pharmaceutical applications [2]. One possible solution is the manufacturing of amorphous solid dispersion (ASD), where the API is molecularly dispersed in a polymeric carrier. HME is a very efficient manufacturing technique for ASDs, but the process inside the extruder is not well understood. In this context, physical models were developed that are applicable to extrusion processes in the food and polymer industry. However, pharmaceutical sub-processes like grinding, mixing, melting and dissolution were not evaluated. The general objective is to model and predict extrusion processes for pharmaceutical applications considering especially these relevant sub-processes [3].

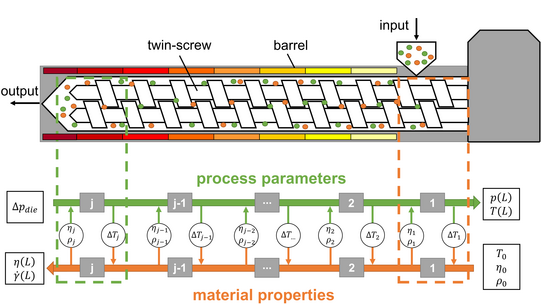

The aim of this project is the development of a predictive software tool, which is based on 1D models to represent the entire extrusion process [3, 4]. The models are implemented with the programming language Python in order to calculate various process parameters and product properties along the extruder in axial direction. Furthermore, an industrial extrusion is performed in order to validate the simulation.

This work is a cooperation of INVITE GmbH in Leverkusen and TU Dortmund within the frame of the industrial-academic consortium Drug Delivery Innovation Center (DDIC).

References

- A. Eitzlmayr, J. Khinast, et al., Experimental characterization and modeling of twin-screw extruder elements for pharmaceutical hot melt extrusion, AIChE Journal, 2013, 59 (11), 4440 – 4450.

- Evonik, Schmelzextrusion verbessert die Bioverfügbarkeit schwerlöslicher Wirkstoffe, www.process.vogel.de/schmelzextrusion-verbessert-die-bioverfueg-barkeit-schwerloeslicher-wirkstoffe-a-317868/ (18.04.2021).

- K. Kohlgrüber, Der gleichläufige Doppelschneckenextruder: Grundlagen, Technologie, Anwendungen, Hanser Verlag, München, 2016.

- J. Pawlowski, Die Ähnlichkeitstheorie in der physikalisch-technischen Forschung, Springer, Heidelberg, 1971.

Curriculum Vitae

| Since 2021 | PhD at the Laboratory of Solids Process Engineering, TU Dortmund |

| 2019 - 2020 | M.Sc. Chemical Engineering, TU Dortmund Master thesis: Development of a vertical setup for determining characteristic screw parameters of co-rotating twin-screw extruders |

| 2014 - 2019 | B.Sc. Chemical Engineering, TU Dortmund Bachelor thesis: Development of an experimental setup for the investigation of periodic liquid-liquid flows in a micro-computer tomography |

| Born | January 16th, Siegen (Germany) |